Today, I want to show you how to diagnose and repair a soldering iron that not heating up. For your information, I use the original heating element A1321 from Hakko and rework station SAIKE 932D.

Step 1: Diagnosis soldering iron- My handle soldering iron malfunctioned. I need to bend the cable cord to start increasing the temperature.

- If the cable cord is straightened, the temperature will not increase.

- I will show you how to repair squeaking noise problems in this post.

Step 2: Removal/Troubleshoot of a soldering iron handle

- Remove 5 pin soldering iron connector from the work station.

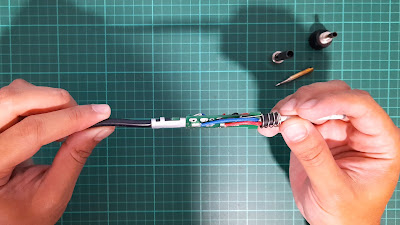

- The soldering job is poorly done, and the wires are folded from the surface view.

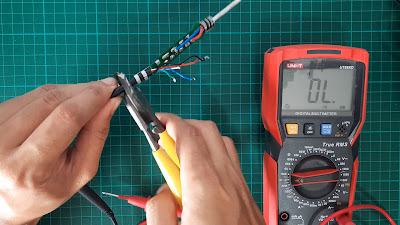

- Measure the resistance of the A1321 sensor and heating element. If the value is outside the acceptable range, replace it. If the resistance value is normal, the cable cord may be broken.

- After troubleshooting, the heat element resistance not detectable (OL) meanopen load or open circuit.

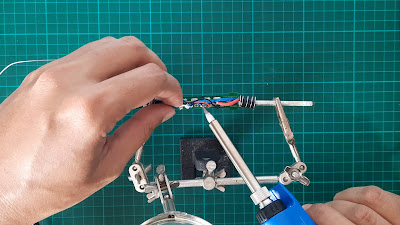

- So, I decided to desolder the wire cord connected to the terminal board.

- However, pin 2 has no continuity and resistance (OL). When I bend the cable cord, pin 2 has resistance and continuity. If I straightened the cable cord, pin 2 had no resistance and continuity.

Step 2: Installation

The link tools and components replacement I used in this video are listed below:

Tools/Components/Items (Shopee):

Tools/Components/Items (Lazada):

Video:

That all from me. If you have any suggestions, please write in the comment section. Thank you for your time 👷.

No comments:

Post a Comment