Let's kick things off with a classic "uh-oh" moment. You're all set to type away on your computer, but guess what? Your trusty keyboard is acting up, thanks to a certain sneaky mouse who decided to take a nibble out of its wire. Annoying, right?

|

| The keyboard was chewed by a pesky mouse! |

Well, here's the good news: you're in the right place. In this simple, no-nonsense guide, we're going to show you how to fix that chewed-up keyboard wire with no tech wizardry required. It doesn't matter if you're a tech pro or just someone with a curious streak – we've got your back.

So, let's roll up our sleeves and get that keyboard back to its old, clickety-clackety self. Time to outsmart that pesky mouse! 🛠️🖱️💻🐭

Step 1: Disassembly

Start by disassembling the keyboard using a screwdriver to carefully remove all internal components.

|

| Removing a screw from the back of the keyboard. |

Step 2: Prying Open the Covers

Gently pry open the top and bottom covers of the keyboard. You can use a dedicated pry tool or a Philips screwdriver.

|

| Be patient and work your way around the edges to avoid causing damage. |

|

| Removing all internal components. |

Step 3: Cleaning

Use compressed air or a soft brush to thoroughly clean any dust or debris inside the keyboard.

|

| Use a soft brush to remove any debris. |

Step 4: Repairing the Wire

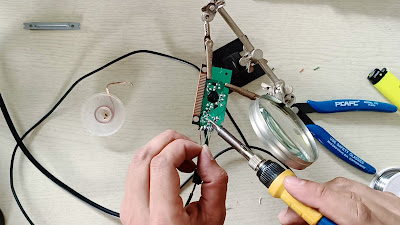

Desolder the broken wire from the PCB (printed circuit board).

|

| Desolder attached the wire from the PCB. |

| |

Replace it with a new wire of the exact length. Measure the length of the damaged wire accurately. |

|

| Strip the wire ends and solder them back onto the PCB, ensuring proper insulation. |

Step 6: Reassembly

Carefully put all the internal components back in their original positions.

|

| Install in reverse order of removal. |

Step 7: Test

Test the repaired keyboard to ensure it's working correctly. It should type normally once again.

| |

| Congratulations! You've successfully repaired your keyboard wire damaged by a pesky mouse. |

The link tools and components replacement I used in this video are listed below:

Shopee: