Industry 4.0, the integration of digital technologies into manufacturing, is having a significant impact on the electronics industry, especially in Surface Mount Technology (SMT). SMT is a technique where electronic components are mounted directly onto the surface of a printed circuit board (PCB), widely used in modern electronics. Industry 4.0 is transforming how SMT electronics are manufactured, making the process more efficient, cost-effective, and reliable.

|

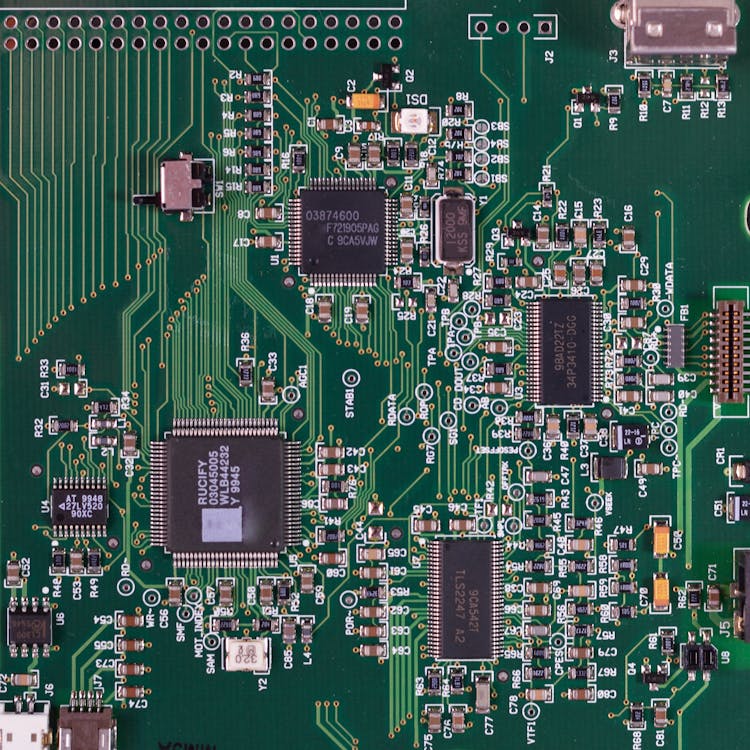

| SMT board (Source: pexels.com) |

In SMT electronics, Industry 4.0 integrates data analytics, automation, and real-time monitoring. By collecting and analyzing large amounts of data in real time, manufacturers can identify and address issues more quickly, leading to increased efficiency and reduced costs. Automation reduces the need for human intervention, improving efficiency and reducing errors. Real-time monitoring uses sensors to quickly identify and address issues before they become significant problems.

Smart manufacturing is transforming the industry in several ways, including improving efficiency, increasing flexibility, enhancing quality control, and reducing costs. Manufacturers can reduce production times and improve overall efficiency by automating and streamlining the manufacturing process. Smart manufacturing allows for greater flexibility in production, adjusting the process in real-time to respond to changing demand. Real-time monitoring and data analytics identify quality issues more quickly, improving product quality. By improving efficiency and reducing waste, smart manufacturing can lead to significant cost savings.

The SMT electronics industry is evolving, and smart manufacturing will likely become more prevalent. As the industry continues to advance, we can expect further advancements in SMT electronics.

No comments:

Post a Comment