In materials science, fiberglass stands as a symbol of resilience and versatility. In our latest experiment, we dived headfirst into extreme heat testing, subjecting a 10 cm section of a fiberglass tube to a scorching 1000°C flame. Join us on this thrilling journey as we unravel the mysteries of fibreglass and explore its limits.

|

| Fiberglass sleeve tube protection up to 600°C |

Step 1: Flame Test

- The experiment commences as a 1000°C flame engulfs the fibreglass tube.

Test flame it with lighter. - Step into the heart of the heat and closely observe the initial changes as the once pristine surface darkens under the intense flames.

1000°C lighter flame as the tube darkened

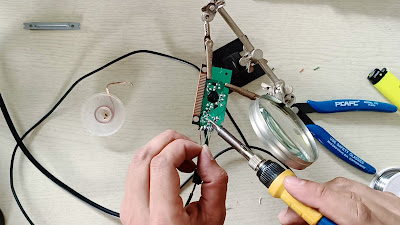

Step 2: Wire Insertion Trial

- Take a daring turn in the experiment by inserting a wire into the fresh fibreglass tube. Witness the trial by the lighter as the wire and tube combo face the flames.

Insert the sleeve into the wire.

Test with lighter. - As the flame subsides, we review the aftermath of the intense heat.

Some external melting from the heat.

The robust fibreglass sleeve endures.

Step 3: Conclusion

In the culmination of our riveting experiment, the fibreglass sleeve has revealed itself as a true hero in the face of extreme heat. Designed to protect against temperatures up to 600 degrees Celsius, our rigorous test subjected it to a blazing 1000°C flame from a lighter. Despite the intense heat causing a visible transformation, turning the once pristine surface black, the fiberglass sleeve showcased remarkable resilience.

The link tools and components I used in this video are listed below: